machining surface finish callout

DennisP Mechanical 21 Jun 07 0457. Machining N9 250 63 N10 500 125 Rough.

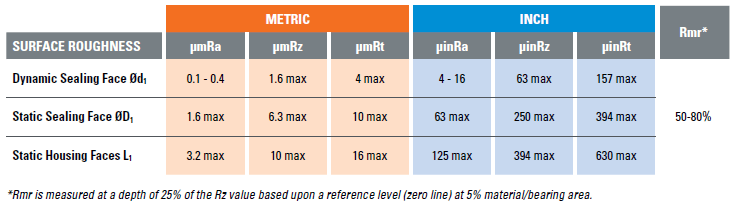

Surface Roughness Finish For Bearings And Seals Hallite

Surface finish refers to the process of altering a metals surface that involves removing adding or reshaping.

. N1 1 0025 Lapping. It is measured in millimeters or microns or microinches. The measurement of a surface finish call-out of 16 microns on a 23 mm by 45-degree chamfer.

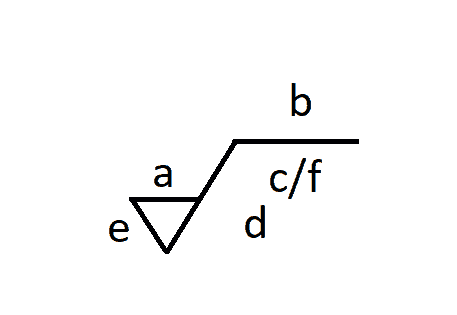

Surface Roughness Terminology. Surface finish specification and comparison. If it is a turned surface then the C probably denotes a circular lay to the finish.

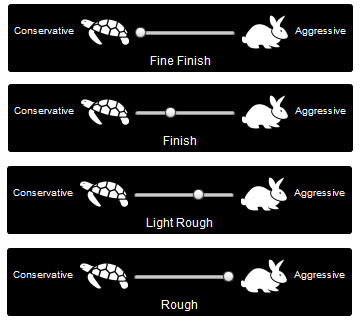

Lets look at a very specific surface finish request. However getting the desired surface finish will depend on cutting parameters such as feed. Machining surface finish influences the quality durability and performance of manufactured parts and components.

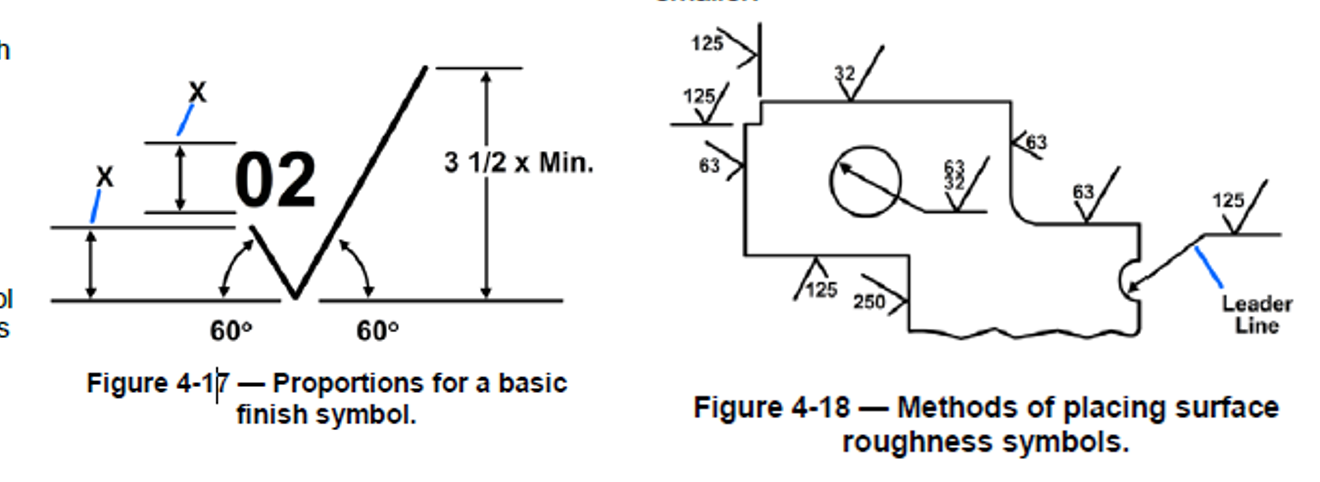

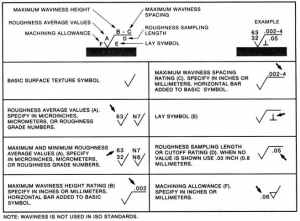

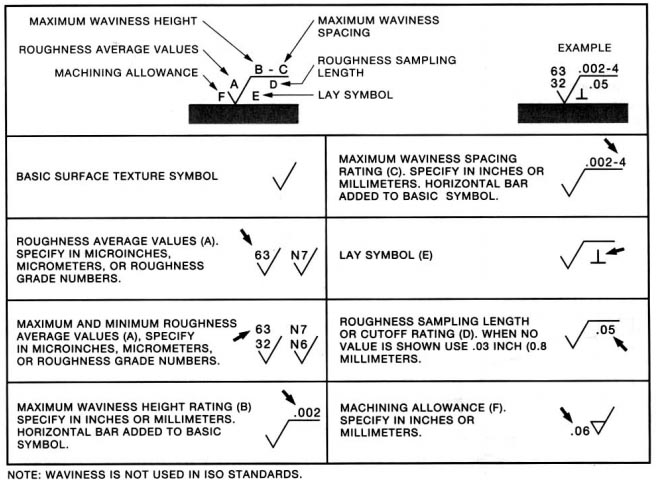

These irregularities combine to form surface texture. Ones rms is to mentally multiply the metric value by 40. The tick symbol is placed on the surface or an extension drawn to it.

Roughness consists of surface irregularities which result from the various machining process. It is a measure of the complete texture of a products surface that is defined by. Machining surface finish callout.

The surface Finish of a machined part is described using some parameters which are called surface finish units. Finish Symbol N Finish R a μinch R a μm Super finishing. These units help design engineers as well as technicians to understand.

There are many variations. If the part is metric then the 82 most likely means an 82. An easy way to convert metric surface call outs to standard US.

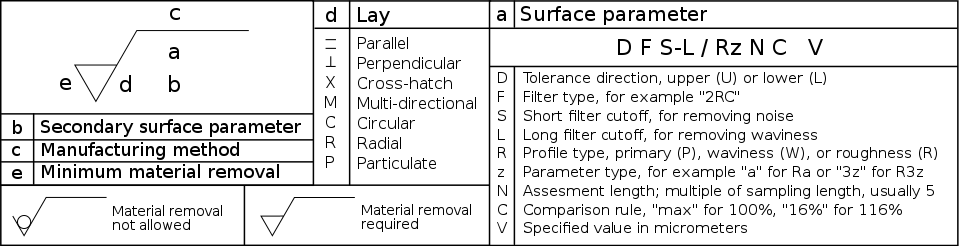

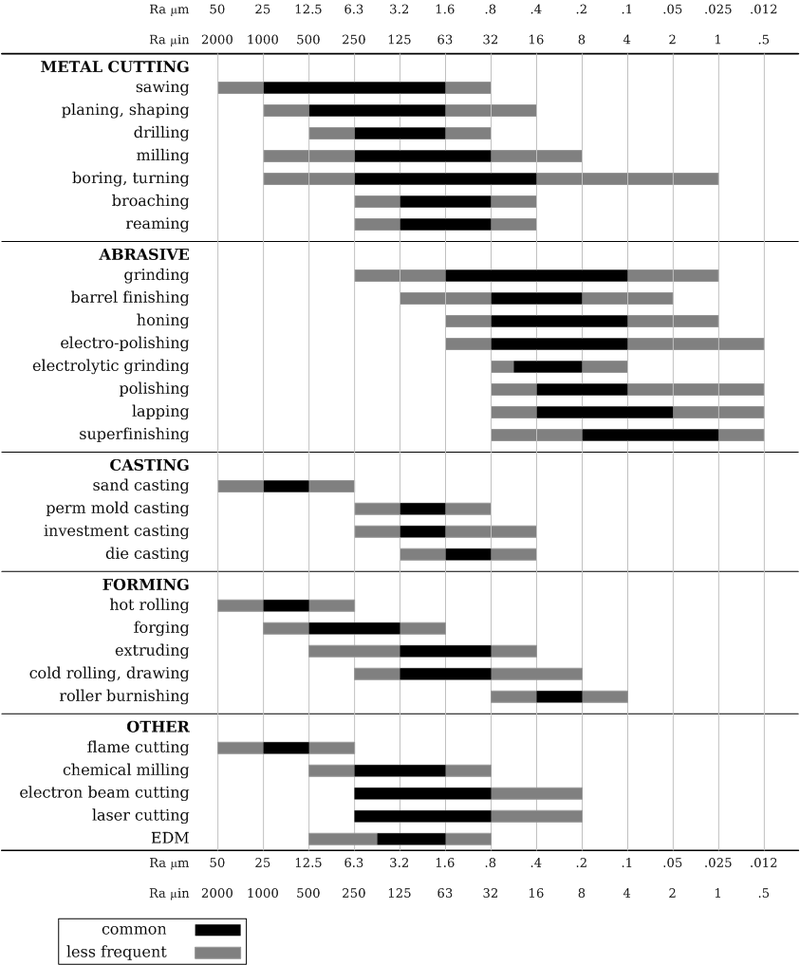

For example 16 63 rms 32 125 rms and 63. Surface finishes are important for the quality of a product during the machining process. This surface roughness indication method pictorially displays information such as the surface roughness value cutoff value sampling length machining method crease direction symbol.

Surface finish also known as surface texture or surface topography is the nature of a surface as defined by the three characteristics of lay surface roughness and waviness. The chart lists the name of the finish the roughness in microns and the applications. The plastic surface finish chart is a guide to the various finishes that can be applied to plastic parts.

June 16 2022 May 5 2022 by Brandon Fowler. The tick symbol is placed on the surface or an extension drawn to it. The details in iso.

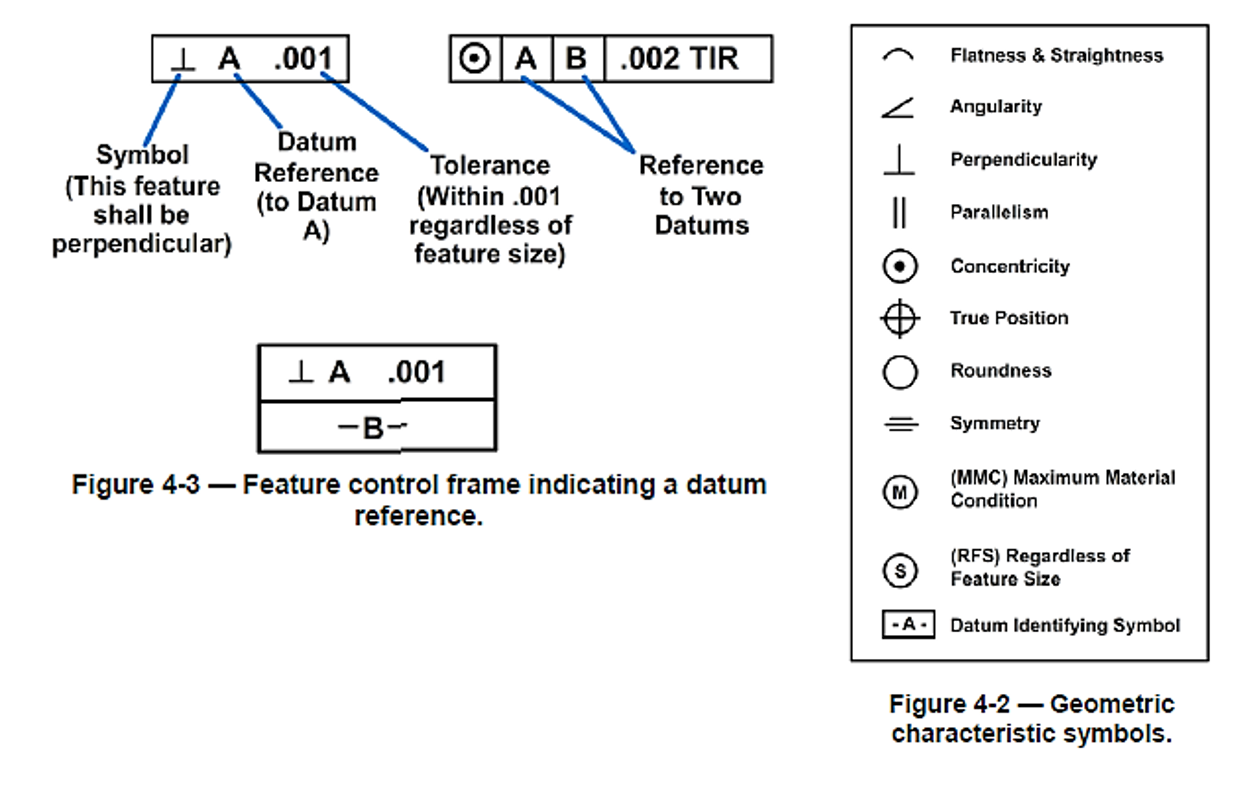

Complete Guide to Machining Blueprint Symbols. For instance when manufactured products possess smooth surfaces. It is the height of the irregularities with respect to a reference line.

A symbol for defining the surface finish of a part. The same applies to finding the best solution for a surface finish requirement.

Surface Roughness Symbols Iso Finishing

The Only Surface Finishing Chart And Guide You Ll Ever Need

The Basics Of Surface Finish Gd T Basics

Complete Surface Finish Chart Symbols Roughness Conversion Tables

Surface Finish Surface Roughness It S Indications Symbols

The Complete Guide To Surface Finishes Xin Tian Jian Precision Mfg Ltd 2022 October

An Overview Of Injection Molding Surface Finishes

Surface Finish Texture Symbols Drafting Gd T Simpliengineering

Complete Surface Finish Chart Symbols Roughness Conversion Tables

Surface Roughness Symbol In Drawings Mechanical Engineering General Discussion Eng Tips

Surface Finish Quality Ra Rz Rt Surface Roughness Measuring Finish

Complete Guide To Surface Finish Charts Ra Rz Measurements Callouts And Symbols Help Engineers

Surface Roughness Symbols Iso Finishing

Anyone Knows What Kind Of Surface Finish Is This R Machinists